Handtmann offers a wide range of automation options for the handling of freshly made products, such as the transfer system for the reliable feeding and depositing of formed products or of portioned products into trays. Automation options are deployed in many different food production processes for meat, dairy, convenience, vegan/vegetarian products and much more. The automation modules RB 371 retracting conveyor, ZB 375 feeding conveyor and TD 387 tray denester are now supplemented by the UB 365 underlay belt and the ES 388 loading and feeding system. Handtmann thus provides medium-scale and industrial-scale food processing companies with flexible automation options from the filling and portioning process to the depositing of products in the packaging solution. Modules such as the Handtmann WS 910 advanced weighing system can also be integrated for additional weight and process control.

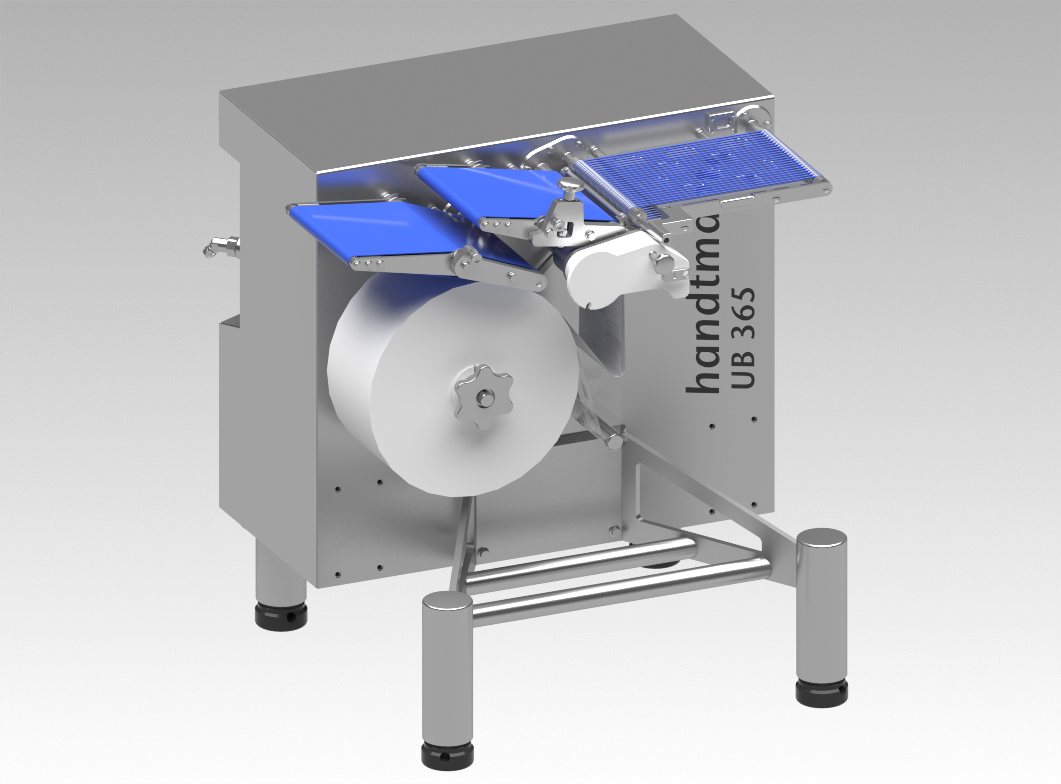

UB 365 underlay belt with aligning, underlaying paper and stacking function

The UB 365 underlay belt facilitates the combination of several optional working functions in the smallest space: aligning, underlaying paper and stacking. All working functions are integrated in the central control concept, which allows the transfer of existing product data and the feedback of newly recorded information. For example, deviations in shape detected by the UB 365 can be transferred to a downstream system as an ejection criteria via Handtmann Line Control. The alignment function allows the precise positioning of the products for downstream working functions and thus ensures high process stability. The UB 365 permits the continuous supply of product underlay that can be customised in length depending on the product size. Different materials and widths can be used as product underlay. Optionally, the products can then be stacked to be able to pack them as resource-efficiently as possible or transferred to a conveyor for further processing (e.g. freezer).

ES 388 loading and feeding system for mince portions in tray packaging

ES 388 loading and feeding system for mince portions in tray packaging

The ES 388 loading and feeding system with a loading performance of up to 90 portions per minute into tray packaging is ideal for minced meat portions and other mince products such as rib burgers and cevapcici. Tool and tray changes within seconds and a central and networked control of the overall system via Handtmann Line Control with central programme change for the entire line achieve a high rationalisation effect. In combination with the Handtmann minced meat line a perfectly coordinated overall solution from the filling/portioning process to the packaging solution.