Partner.sciencenorway.no – One third of man-made global greenhouse gas emissions are due to food production. However, everyone needs food, and it is therefore urgent that we find new ways of producing food that have less of an impact on the environment whilst also being profitable for the producer.

Additionally, we know that food should be processed as quickly and as gently as possible to preserve quality and nutrition.

Fast, gentle and energy-saving ways of producing and preserving food have been the focus of the four-year international research project iNOBox. The project investigates six innovative processing technologies: high pressure, microwaves, pulsed electric fields, ultrasound, UV light and plasma-activated water.

Scientists, food manufacturers and equipment suppliers have collaborated in order to document the effects these technologies have on food and food production.

Increase shelf life to reduce food waste

One of the most important ways to save the environment is to stop throwing food away. In Norway, we throw away over 450,000 tons of food every year, often because it has passed its expiry date.

“We know that there are major differences between different raw materials and products when it comes to environmental emissions. Despite the fact that fruits and vegetables produce low levels of emissions, these foods have a short shelf life. Therefore, it is really important to give them a longer shelf life and avoid having them end up in the rubbish,” project manager Tone Mari Rode says.

How sustainable is food processing?

When sustainability is calculated, greenhouse gas emissions and shelf life are often studied. However, emissions associated with things such as the production of equipment and transportation must also be taken into account.

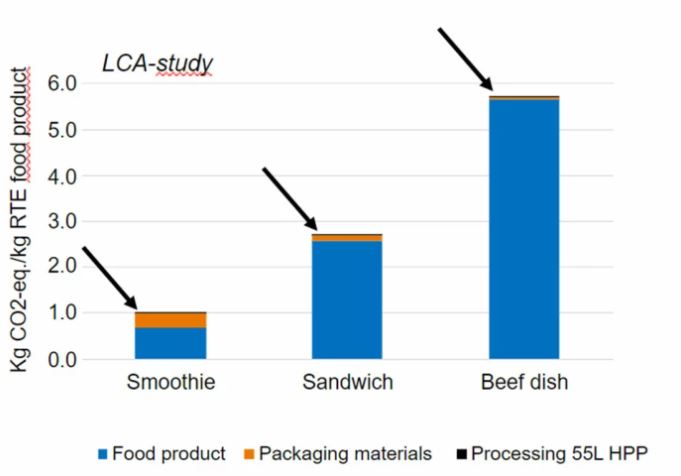

In order to get the whole picture and have the opportunity to compare products, scientists use ‘life cycle assessments’ – a systematic review of the environmental impact in all processes related to the type of food, from when the seed is sown in the soil or an animal is bred, all the way up until the food is consumed.

Norsus has investigated a number of products using this method in order to find out the role that food processing itself plays in the emission accounts. Among other things, they compared the CO2 emissions produced by a smoothie, a sandwich and a beef dish.

Processing to improve food

Many consumers are sceptical about raw materials undergoing treatment in order to improve them. Many believe that the least amount of processing is the best, but this is not always the case.

For example, some people who suffer from allergies can eat nuts that have been treated with heat, but not raw. The allergens associated with allergies are destroyed when the nuts are roasted, while other proteins are not affected.

Can processing with the use of new technologies remove specific proteins from foods that cause allergic reactions?

These types of analyses have been carried out by the Norwegian Veterinary Institute and the Dutch partner TNO. They have investigated the extent to which the new processing technologies can remove specific proteins that can cause allergic reactions.

Unfortunately, people who are allergic to eggs are going to be disappointed – the egg analyses showed no differences between raw and processed eggs in terms of allergenic proteins.

Processing can affect the body’s ability to absorb nutrients from food. Nofima has simulated digestion in the laboratory, and specifically investigated the protein digestion of foods that have been processed using the new technologies.

The results showed that treatment with the different technologies does not affect the protein digestion of any of the foods, except in a ‘smart yoghurt’ – a yoghurt that was made using combinations of technologies. The protein digestion was better in this yoghurt than in traditional processing.

Great potential for sustainable processing

As new technologies become available, it may take time for them to become known and adopted. In the food industry, there are several factors that determine whether a technology is interesting to invest in.

Firstly, it must be known and accessible, and interesting to use as part of or a replacement for processes that are already in use. It must also be an affordable investment, and if the technology is to improve a product, the customer must feel that the new changes in the product are for the better.

Food products that have never been made before, or that have been made in new ways, must have EU ‘novel food’ approval in order to enter the European food market.

A similar ‘new food’ regulation can be found in Norway that has common rules and approvals with the EU. Previously, this has entailed a long and demanding process for food manufacturers, but has now been revised and made somewhat smoother.

Nofima has studied these regulations and encourages food manufacturers to seek help from the Norwegian Food Safety Authority and other producers. Nofima’s research shows that transparency between manufacturers is important for the industry to succeed when it comes to innovations.