At the heart of the Hoegger® X3 Press is servo hydraulic-controlled press technology that provides fast and accurate pressing. Through the controlled application of force, the Hoegger® X3, which is ideal for bacon production, enables precise and efficient pressing of natural shapes and even large belly deformations. This results in better shaped products which in turn leads to more homogenous portions while slicing that significantly improve the slicing yield. It reduces belly cracking and keeps deep wrinkles to a minimum. While Hoegger® X3 technology is ideal for bacon, it also provides extremely accurate pressing of fresh meat and specialties.

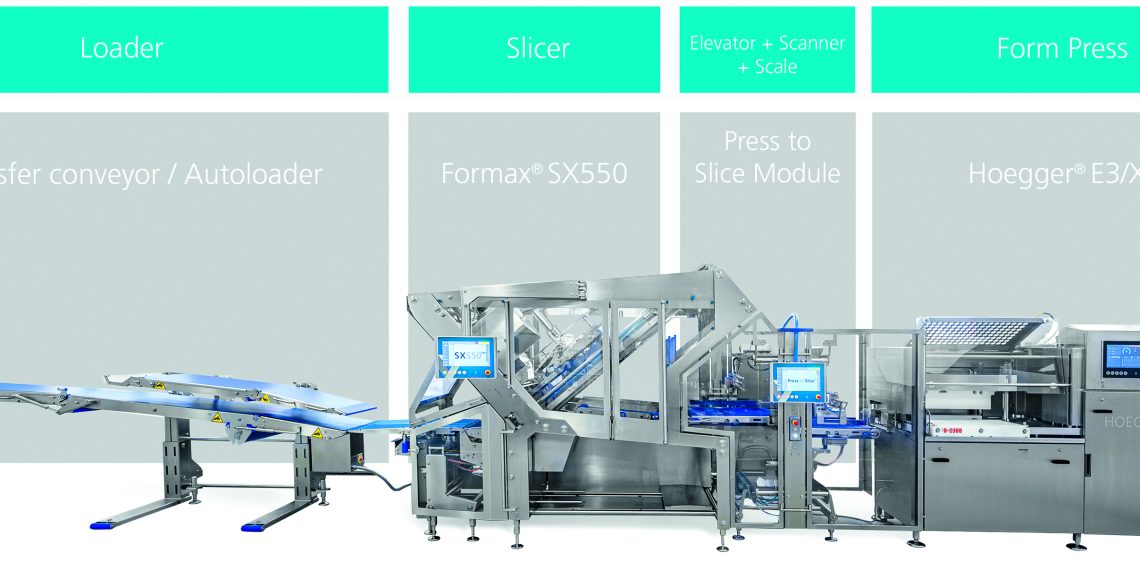

Superior portion control with the press-to-slice module

Provisur’s next-generation press-to-slice module includes a 3D scanner and scales that achieve high-precision evaluation of weight, shape, and density of the product. This data is transmitted to the slicer and enables the slicer to produce accurate portion weights, consistent slice thickness, and exact slice counts – in fact, the scanning technology determines how to portion each log before the first slice is cut. There is a continuous feedback loop from the slicer to the press-to-slice module, enabling speedy adjustment of parameters to maximize yield and reduce waste.

Unrivaled efficiency, maximum yield: the Formax® Slicer SX550 and SX330

The brand new Formax® SX550 is a high-capacity slicing system that works seamlessly with the press-to-slice module. The SX550 has a 550 mm wide throat to fit a maximum amount of product. It provides better portion control and is ideal for high-speed bacon production while also slicing cold cuts, cheese, cured meats, and specialties. The SX550 has two independent product drives and can slice two bacons at the same time, making it a high-yield system that maximizes throughput. Smaller products like salami the SX550 can slice multiple products at the same time.

The smaller Formax® SX330 slicer delivers high throughput with a small footprint and flexible configuration. It is extremely versatile and can slice multiple SKU’s (Stock keeping units) per day. At 330 x 160 mm, it also has the largest cutting throat in its class. This innovative slicing system, with its involute blade, ensures top performance with a cutting capacity of up to 1500 cuts/minute, which is unrivaled for this size of slicer.

Automation, hygiene, sustainability: meeting the needs of food processors

Through the company’s global network and Innovation Centers, Provisur is at the cutting edge of developments in the food processing industry. Gerd Stratenwerth, Sales Manager EAPMEA at Provisur, points to two independent trends: “On the one hand there is a trend for very flexible line configurations that serve many different products, and on the other hand there is a need for high-performance lines optimized for only a few products. With our press-to-slice integrated line, and our Formax slicers, we provide outstanding solutions for both of these trends.”

The versatile loading and unloading modules enable fully automatic product lines. The high level of automation has numerous advantages for food processors. It improves hygiene by keeping manual interventions to a bare minimum and has the added advantage of reducing the number of operators needed to run the line. This saves labor and thus helps overcome the acute labor shortages which the industry is currently facing. The press-to-slice line has been developed for the requirements of Industry 4.0. Fully integrated electronics on every module allow for smooth data exchange, again maximizing efficiency and yield. Energy-saving modes like reduced energy consumption in idle mode as well as highly efficient servo units boost the line’s sustainability performance.

“The seamlessly coordinated modules increases yield and profitability,” explains Gerd Stratenwerth. “But better yield also leads to a significant reduction in food waste. For us at Provisur, saving food and improving yield go hand in hand.”